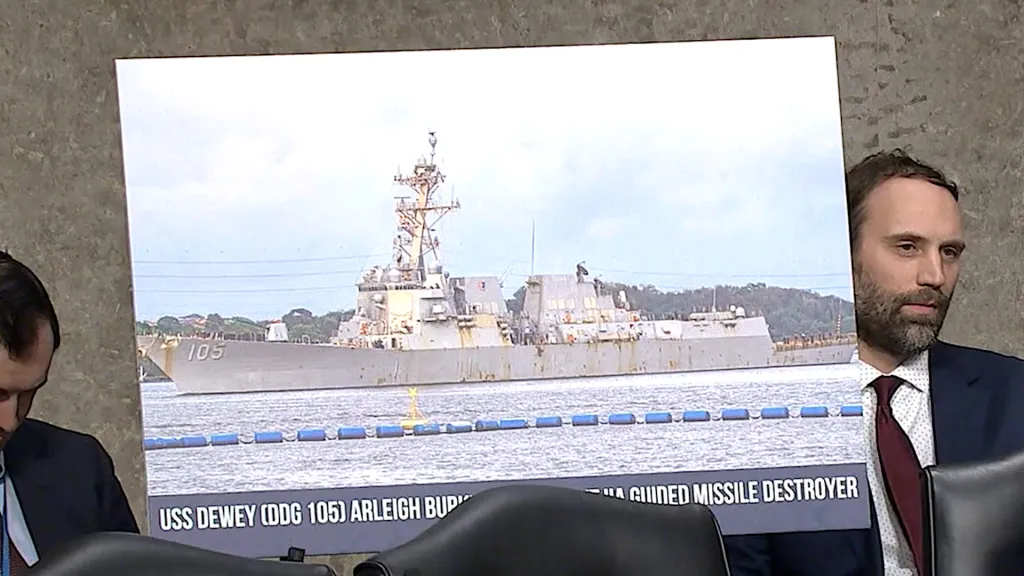

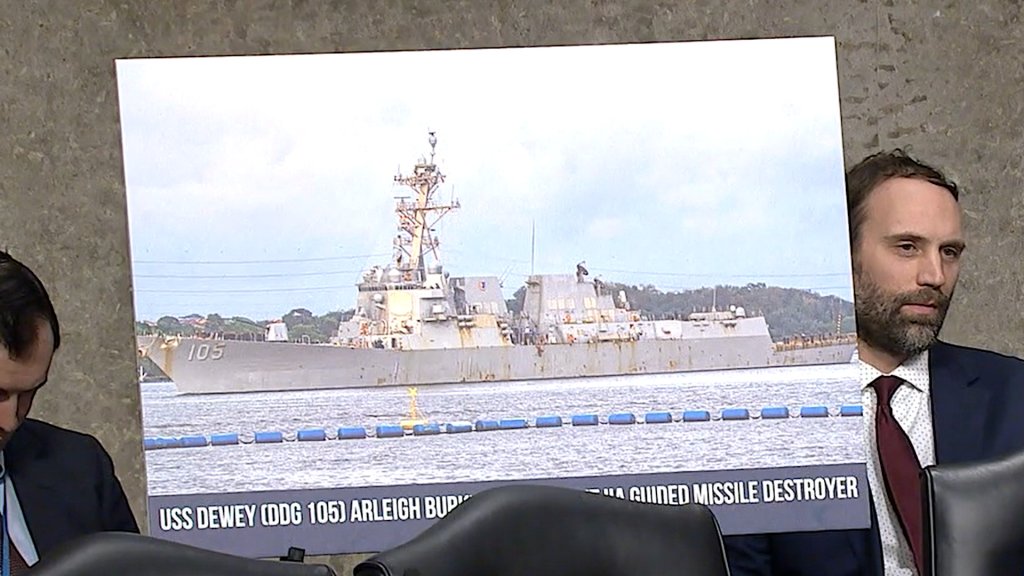

For years, the Navy has essentially ignored the issues associated with rusting ships, said the man officially tasked with fixing the problem. However, it became a priority in February 2025 after President Donald Trump saw a picture of the Arleigh Burke class guided missile destroyer USS Dewey covered in “running rust” as it pulled into Singapore last year. You can read more about that in our original story here. The Navy’s chronic rust issue and the negative optics surrounding it is a topic we have been covering for nearly a decade.

“We know what to do, but we choose not to do it,” Mark Lattner, director of the Navy’s Ship Integrity and Performance Engineering, Naval Systems Engineering Directorate, said during a panel at the Surface Navy Association’s annual symposium on Tuesday that TWZ attended. “And we choose not to do it because there’s always some other problem I’ve got to fix. I don’t have time. Our corrosion can wait. And so we don’t implement the fixes.”

Finding a solution to the Navy’s rust problem became one of Lattner’s main missions in the wake of the fallout from Trump’s late-night texts to Navy officials demanding answers.

While it can make ships look like “rusting garbage scows,” Lattner noted, this issue isn’t just a matter of aesthetics. Unaddressed rust and corrosion on Navy ships has downstream effects on maintenance and readiness.

Some of the solutions are “simple,” Lattner suggested, like wider use of polysiloxane paint, “originally developed as an anti-graffiti paint, very robust, very good paint, easy to clean.”

“It might be as simple as putting a good scupper on the ship, diverting the water away from the ship,” Lattner said of the drain openings on a vessel’s bulwark. “If we can use materials that are inherently less prone to rust, that’s great. That includes composites, includes stainless steel, other things like that.”

Reducing the work load of sailors and the margin for error is another solution.

“How do we make it more sailor friendly, things like single pack paints, right?” Lattner noted. “Sailors mix multiple components together. There’s always inherent things that could go wrong. If you use a single pack thing, they break the pack open, they mix it together. They’re good to go. Try and take away work from the sailors.”

Having sailors do more rust-preventative maintenance themselves will also help.

“Don’t just cover up the rest by painting it over again,” Lattner stated. “Just tell the sailor to go and clean it off. And we’ve got special cleaners that make it easier to clean it.”

After being asked by the Chief of Naval Operations how be knows he is getting a handle on the problem, Lattner answered that there is a new evaluation process.

“We’ve identified ways to input the data and go around and survey the ship so we actually know what’s going on with the ships,” he said. “In this particular thing, we developed an app that you use on your phone, and so when the TYCOMS walk around and inspect the ships, they can actually kind of check off, ‘yeah, this looks good. This doesn’t look good. This needs improvement.’”

“The ships come up with a grade,” Lattner added. “One of the things we did, rather than make it just qualitative, we actually give them a quantitative number. So I can actually say this is how good ships are.”

There are also improvements in training underway, with teams teaching sailors the best and easiest ways to paint ships.

“These guys are experts,” said Lattner. “They bring the technology, the tools, all the things that are holding sailors back from being able to do the job properly.”

Teams of contractors are helping to do some of the work that sailors can’t, something that is key given how the Navy avoids keeping ships offline for extended periods of time.

These teams “go in there and actually execute the corrosion control work They’ll install the things like the scuppers. They’ll put on the films. They’ll do some preservation. They’ll do cleaning, getting the ships better. And what we’re doing is not trying to eat the elephant all at once, but one bite at a time, right?”

Some of the solutions go beyond what the Navy can do on its own, Lattner pointed out. Industry has a big role to play too.

“They can help actually do the preservation work. They can help do the development of technology. Even though we have a lot of good technology, and we know what we can do, we’re always looking for better ideas. Are there better ways to do preservation? Are there better ways to remove the old paint? Are there more robust solutions that we can implement?”

Lattner also seeks changes in future ship designs that will reduce rust and corrosion and improve the ease of maintenance.

Even if all these solutions are implemented, the Navy will never have the same kind of shiny ships that cruise lines do.

For instance, Carnival Cruise Line is “constantly touching things up,” Lattner proffered. “They swarm the ship when it gets back in, touching things up, keeping things up to speed. When they do [maintenance in port] availabilities, their availabilities are very tight, right? They’re short. They’ll, they’ll never use a company again if they don’t meet those, those timelines.”

The Navy does not have that luxury.

“We in the Navy are unfortunately kinder and gentler, right?” Lattner postulated. “So right, wrong or indifferent. I’m more tolerant. The longer I wait between different evolutions, the more likely things are going to go south, right? And we’ll have to work with that, right? There’s no great solution.”

Contact the author: howard@thewarzone.com